Get This Report about 24??media

Get This Report about 24??media

Blog Article

The Ultimate Guide To 24??media

Table of ContentsThe Main Principles Of 24??media Our 24??media IdeasThe Best Guide To 24??mediaOur 24??media Statements24??media for Dummies

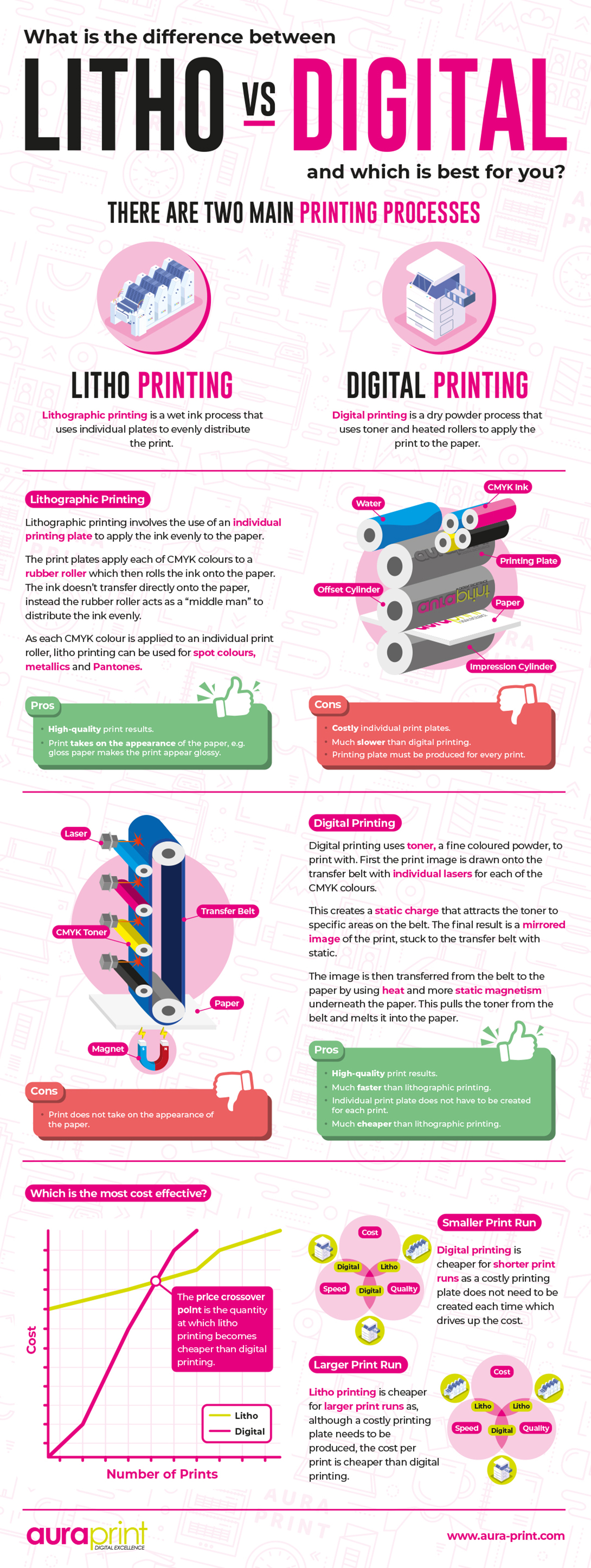

Offset, gravure printing and flexography are one of the most usual sorts of traditional printing in the product packaging area and each entails moving the image from a plate to the surface area. To do this, first the plate requires to be created, and it is the development of these plates that take time, and cost money.According to PMMI, electronic printing permits brands and makers to react promptly to client needs while improving the supply chain, minimizing warehousing price and waste, and taking pleasure in faster time to market. That all noises wonderful, but just how does this modern technology do all that? The major differentiator of these modern technologies is that there are no set-up charges and no plates with digital printing.

This results in quicker turn-around time and lowers cost when utilizing digital printing.

Speedy production suggests obtaining your item to market quicker. It likewise indicates it's less complicated and faster to make adjustments later on, when you change a recipe, add a SKU, or produce seasonal product packaging. Digital printing is extremely versatile, so it's very easy to make adjustments to the package style quickly. It all goes back to the plates.

The Best Strategy To Use For 24??media

A lot more inventory can imply more waste in the future. With standard printing methods, short-run printing is just not feasible. Since a great layout can make or damage your item, digital printing consistently develops high-grade, clear and vibrant graphics each time. Digital printing on flexible bags adds the brilliant, vibrant, and specific graphics that almost beckon consumers to reach out and touch them.

Loading ... Are you aware of the benefits of digital printing? Continue reading to comprehend when electronic printing can be the very best feasible remedy for your service. Do you understand why digital printing has come to be the favorite option of some businesses? Both countered and digital printing have their area in the printing industry.

In this short article, we will certainly review the benefits of electronic printing to aid you much better understand if digital printing is just what you need. Merely put - digital printing prints product straight onto the paper.

See This Report on 24??media

As electronic printing continuously progresses, it supplies more possibilities and greater result top quality every day. In many cases, the print top quality can be as high regarding counter printing. As years go by, digital print is becoming extra accessible, with improved rate and high quality. This is just the reason printing companies are including electronic printing to their deal.

For countered printing, if any type of blunder goes unnoticed before creating the plates, there will be a high cost of developing a brand-new one. However, with electronic printing, this is not the situation. Everyone always really hopes there will certainly be no mistakes, knowing the cost of fixing them if they happen is always an excellent concept.

This suggests every piece will certainly look the exact same, so the opportunity you will require to discard any of them since of inconsistencies is low. Considering that a proofing example is printed on the exact same maker as the product itself, color proofing is very precise. Any kind of troubles with shade will certainly be visible on the evidence, and hence it will certainly be feasible to change it prior to publishing the entire run.

The Ultimate Guide To 24??media

Digital printing, on the other hand, needs very little configuration. This is great when you are in a hurry to obtain your printed products.

This implies even more requests for digital on-demand print manufacturing. Every customer appreciates an individualized message. Among the benefits of electronic printing is that personalizing your marketing products could not be less complicated. Cost-effective, smaller batches allow businesses to tailor each order. Have a back-to-school sale? Make a flyer to target parents and an additional one to target the trainees.

Digital printing is the ideal option for variable data printing, like custom codes and addresses on direct-mail advertising. With electronic printing, it is less bothersome to make last-minute changes to your layout. Often the very best kind of communication is not electronic. In these cases, relying upon digital printing can make sure these orders have a very little ecological effect.

The Main Principles Of 24??media

There is likewise no demand to clean the plates after printing. The advantages of digital printing include that there is no waste from added or leftover ink, paper, or chemicals due to the fact that only what's required gets published. - for very short runs, electronic printing is the means to go, certainly.

Gone are the days of complex configurations and lengthy turnaround times - electronic printing has actually revolutionised the print sector. The printing globe has actually come a lengthy means considering that the days of Gutenberg's printing press. The brand-new regular is streamlined processes and cost-efficient options for publishing onto virtually anything you can think of.

Report this page